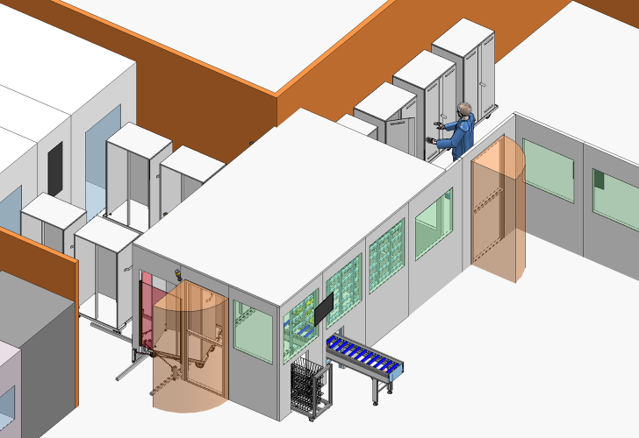

By applying a buffer system at the CSSD you get a more control over the sterilization process. The FOSKE platform uses the Hospital Information System (HIS) to determine which nets and baskets are given priority and which nets and baskets can be temporarily stored.

The storage system CSSD has a double function. On the one hand, the ready nets can be temporarily stored, so that the washing racks can be immediately returned to the dirty room. On the other hand, the process-logic is realized in the further process from the storage of baskets (for example, the urgency handling, collecting distribution location, sterilization batches, etc.). This is how demand-driven work becomes a fact.

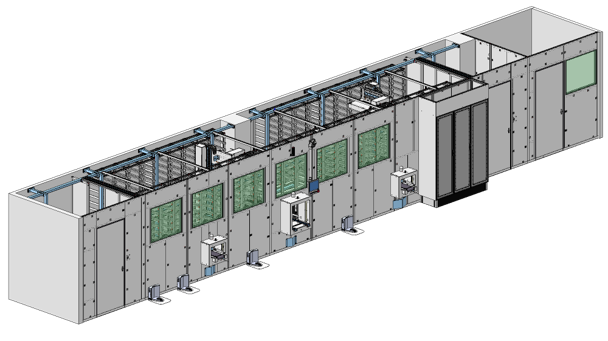

- Completely safe due to extensive contamination control research

- Process optimization (managing capacity, smoothed division of labor over the day, handling urgency)

- No more separate racks for nets necessary in the department

- Nets are stored in a closed warehouse with stable environmental influences

- Safety, both for the user and for the product, is guaranteed

- Space-saving storage in height

- Never lose a basket again (track & trace)

Functionalities

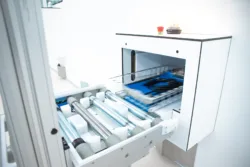

- Storage of packed and unpacked baskets

- Storage in height (space saving)

- Automatic stacking of baskets

- Automatic creation of sterilization batches

- Manual outfeed of baskets possible

- Enables track & trace of baskets