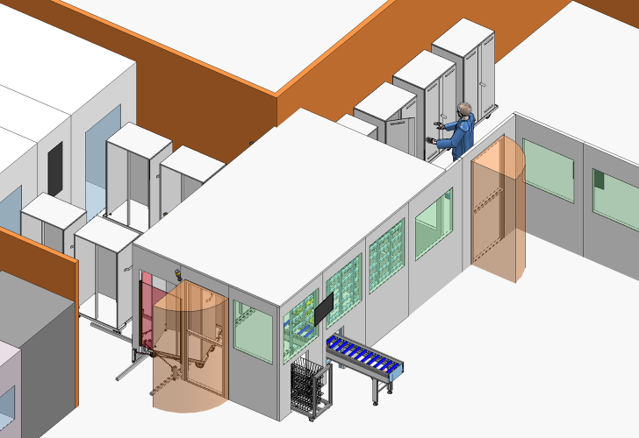

The cleaned empty transport carts are transported from the cart wash to the loading station. Empty transport carts can also be supplied (e.g. for endoscopes). The sterile basket stacks are automatically destacked, inspected by means of vision, scanned and fed into the loading station.

Based on current network information from HIS (e.g. department, prioritization), the baskets are automatically placed in the transport cart or buffer rack (in the loading station) by a pick & place system. Transport carts that are ready (filled) are automatically exported to the sterile lock ready for collection.

In summary, the loading station for transport carts offers the following advantages over existing situations:

- The physical strain on the CSSD employees is greatly reduced (heavy lifting and pulling movements are eliminated)

- Optimal loading of transport carts (baskets clustered per department, urgent handling)

- The transport carts are loaded automatically

- No more separate racks for nets/baskets necessary in the department

Functionalities

- Automatic feeding of stacks of sterile baskets

- Automatic destacking

- Control sterilization tape using vision technology incl. reject

- Automatic loading of transport carts with baskets